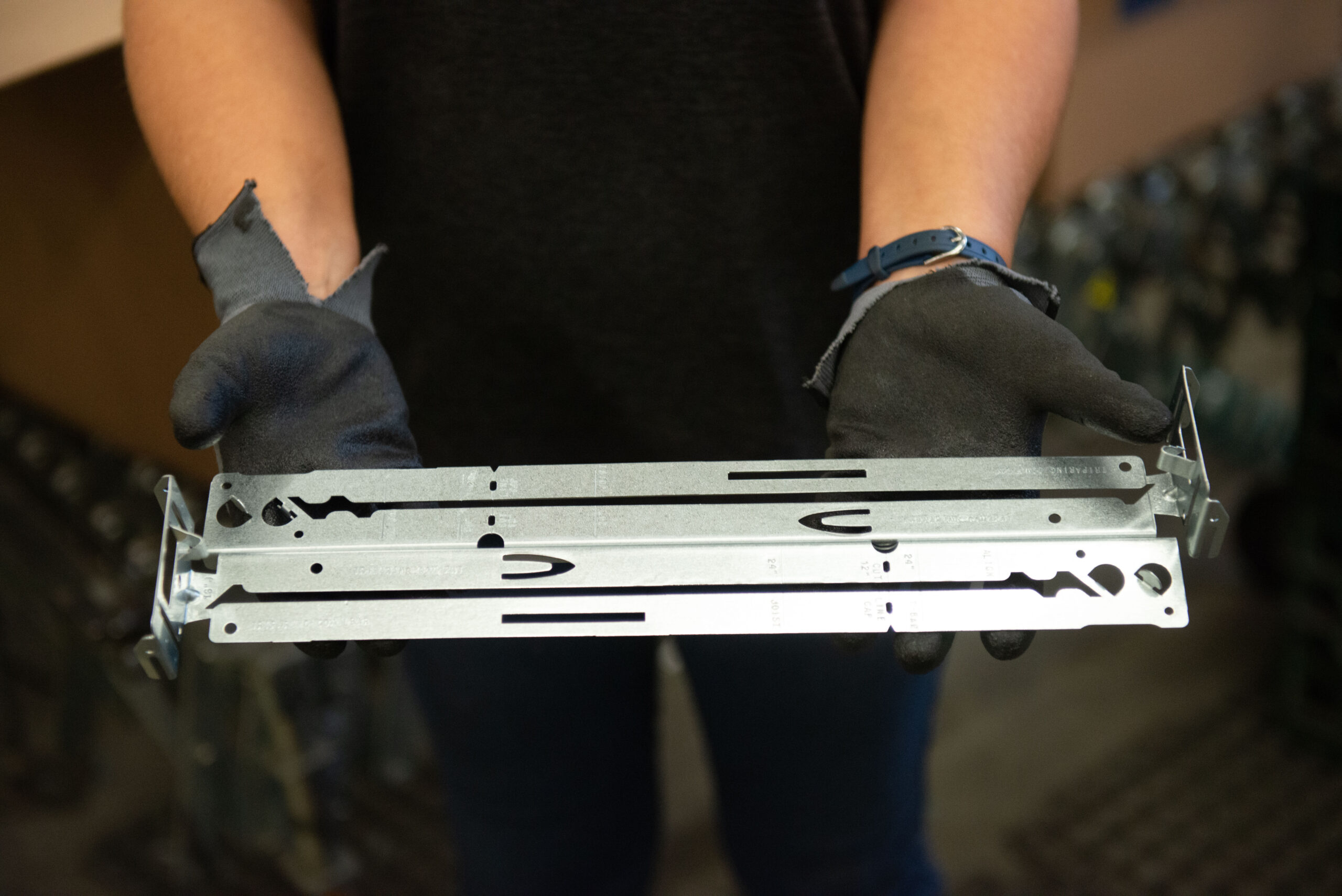

Full selection of stock components including Plaster frames, I.C. Boxes, Junction boxes, Brackets, Hanger bars, canopies for UL1598.

Tripar®, Inc is best known as a lighting component manufacturer for architectural and commercial lighting OEMs who demand quality and who value our deep understanding of the lighting industry and metal components.

We are constantly evolving to stay ahead of market trends to ensure we always offer the best products for the lighting market. We produce a full range of metal components for the lighting industry, including:

- I.C.Boxes

- Retrofit Components

- Junction/Driver boxes Accessories

- Plaster Frames

- Light Fixtures and Lamp Parts

Metal Stamping

With over 100 presses, 1500 dies, in-house die design & toolroom, and a wide selection of coil material, Tripar’s metal stamping manufacturing capabilities include progressive stamping, blanking, punching, bending, engraving, marking, embossing, rolling, drawing and deep drawing, offering reduced cost, improved accuracy and surface finish.

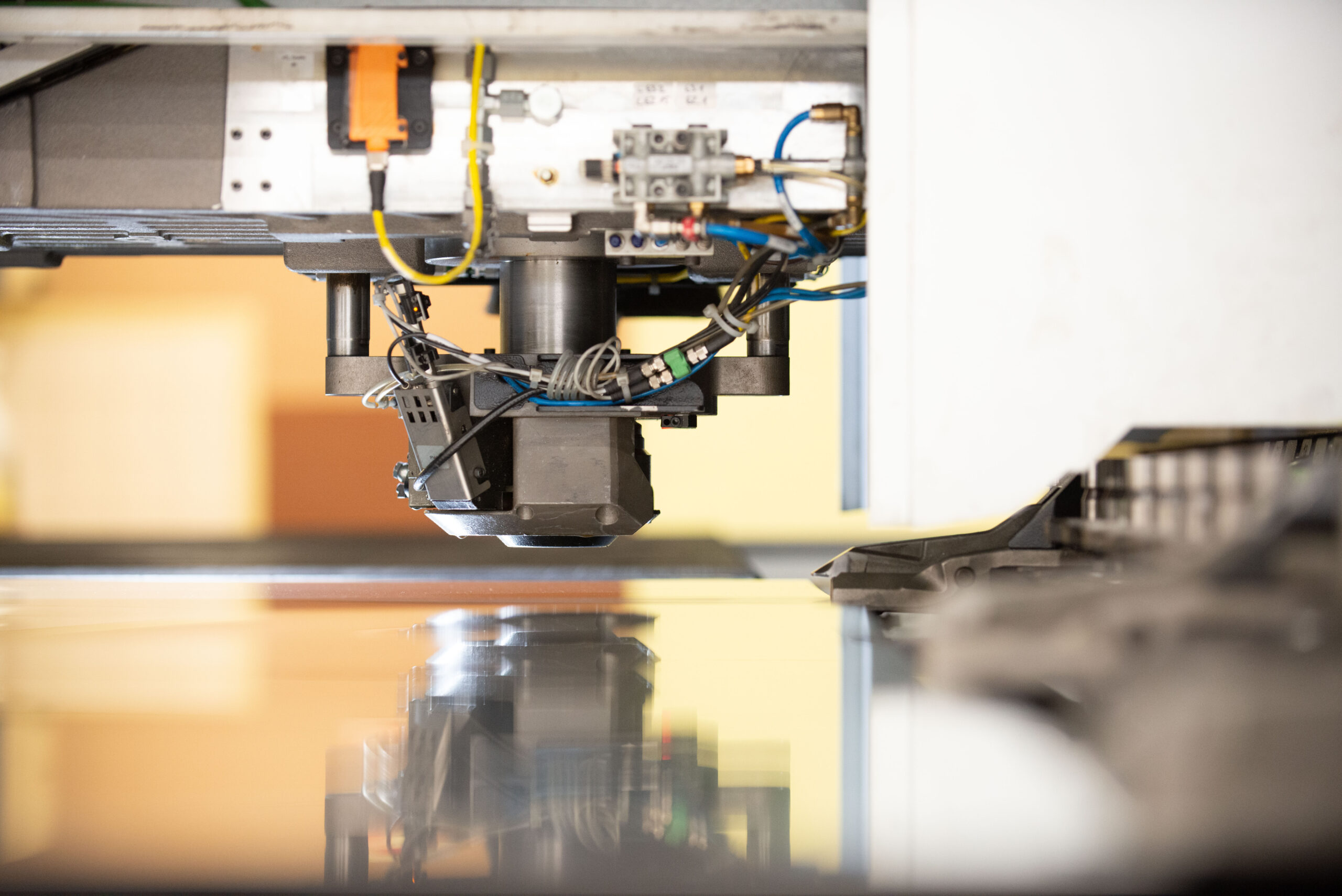

CNC Fabrication

Through Tripar’s vast CNC capabilities and experience, we manufacture a wide range of sheet metal components using equipment and processes such as laser cutting, punching, press brake, metal forming, spot welding, shearing, riveting, clinch joining and assembly.

The Tripar Advantage - What sets us Apart

Tripar is uniquely positioned to support our clients at every stage of the manufacturing life cycle, allowing them the ability to scale, reduce cost and succeed. This is achieved through our range of metal services; engineering support for all pre-production requirements, CNC metal fabrication and metal stamping capabilities to produce a vast range of metal components in multiple industries, with quantities ranging from prototypes to millions of units annually.