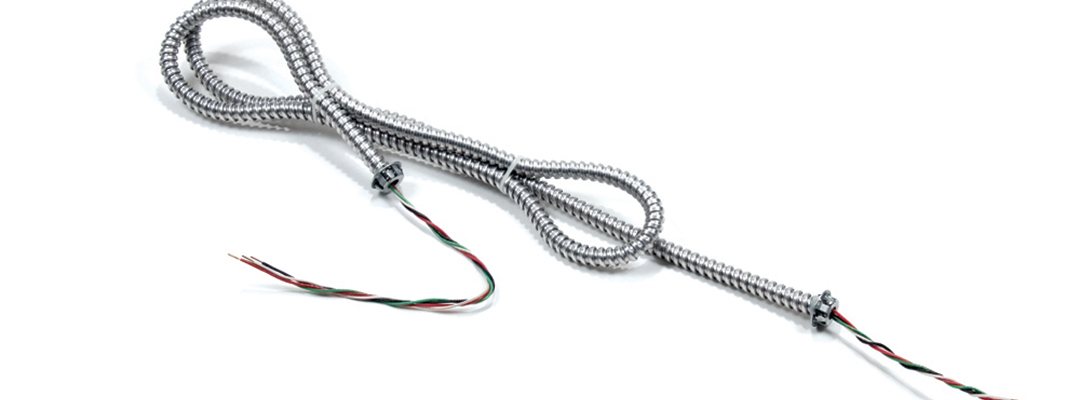

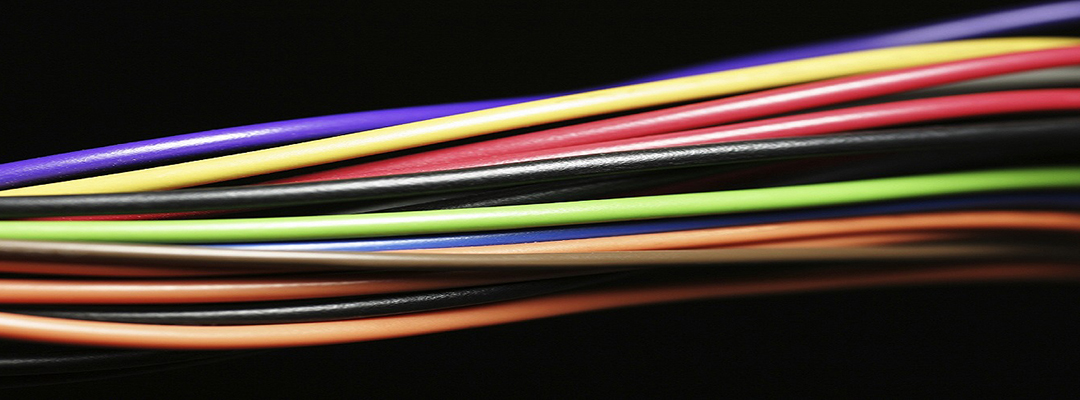

Roytec Industries manufactures custom electrical wire harnesses and electrical assemblies in highly automated plants in the US and Mexico. Its skilled, efficient workforce provides quality, turnkey solutions for OEMs, economically fulfilled from centrally located warehousing and distribution facilities. Roytec has more than 20 years of experience in cutting and stripping a wide variety of wires, ranging from awg 32 wire to 535 MCM cable, from single conductors to multiple conductors, as well as numerous insulation types and specialty projects. Prototyping and reverse engineering, and complete documentation services are offered.

Custom Wire Harness and Electrical Assembly Manufacturing:

- Highly automated wire processing equipment for turnkey production, warehousing and distribution

- Prototype, low-volume, and high-volume capabilities

- ISO 9000 Based quality system; Founding member WHMA

- 26,000 sf facility in Woodstock, GA

- 50,000 sf facility in Monterrey, Mexico

- Hot stamping, inkjet and labeling

- Box build assemblies and cabinet enclosures

- Flux, tin soldering

- Harness braiding

- Automatic cut, strip and terminate

- Kitting and bundling

- Tube marking/heat shrink marking

- Sonic welding

- Braiding

- Prototypes

For more information about Roytec Industries please visit www.roytecind.com